Discover a professional 3D printing powder supplier

Can 3D Printers Truly Publish Metal? The Fact May Shock You!

(can 3d printers print metal)

Picture holding a tiny steel wrench, its grooves smooth and precise. Currently visualize it wasn’t made in a manufacturing facility yet published layer by layer, like a high-tech cake. Sounds like science fiction? Not any longer. The globe of 3D printing has actually broken the code to printing metal, and it’s improving every little thing from rocket parts to fashion jewelry. Let’s study exactly how this wild innovation works and why it’s such a huge deal.

To begin with, yes– 3D printers can print steel. But forget the plastic spaghetti-like procedure you have actually seen in enthusiast printers. Metal 3D printing is an entire various monster. As opposed to pressing thawed plastic via a nozzle, metal printers utilize lasers, electron beams, and even glue-like binders to fuse metal powders into strong items. It resembles baking a cake, if your oven shot lasers and your flour was constructed from titanium.

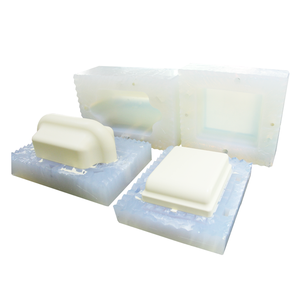

So how does it actually work? Many metal 3D printers begin with a bed of fine steel powder– believe stainless-steel, titanium, or perhaps gold. A high-powered laser or electron beam after that zaps the powder, thawing it into exact forms. Layer by layer, the machine repeats this procedure, developing the object piece by piece. Some methods, like binder jetting, miss the lasers completely. Instead, they utilize a fluid glue to stick steel fragments with each other, then bake the glued item in a heating system to solidify it. Regardless, the outcome is a solid steel component, all set for activity.

Why go through all this problem? Standard metal production commonly involves cutting, welding, or casting– procedures that waste product and restriction layout flexibility. 3D printing allows designers create complex shapes that are impossible with traditional methods. Think of a cooling air duct inside a jet engine, twisted like a cracker to optimize air flow. Or a customized medical implant designed completely for a person’s bone. With metal 3D printing, these ideas aren’t just possible– they’re already happening.

But it’s not all rainbows and laser light beams. Printing steel is costly. The devices cost hundreds of thousands of dollars, and the metal powder isn’t cheap. And also, the procedure is sluggish. Publishing a single component can take hours and even days. And allow’s not neglect safety– those metal powders are super fine and can be eruptive if mishandled. You won’t see a metal 3D printer sitting on your desk beside your coffee mug anytime quickly.

Still, the benefits are big. Aerospace companies use metal 3D printing to lighten, stronger components for airplanes and rockets. Lighter components suggest much less gas melted and reduced costs. Medical professionals print personalized titanium implants for individuals, lowering surgical procedure time and enhancing recovery. Even artists are participating the activity, crafting elaborate metal sculptures that would’ve been impossible to sculpt by hand.

What regarding everyday things? Right now, metal 3D printing is primarily for specialized industries. Yet as the tech enhances, prices will go down. Perhaps someday you’ll print a substitute car part in your garage or style a special steel wedding celebration ring on your laptop. The future isn’t below yet, yet it’s obtaining better every day.

Not all metals are very easy to publish. Some, like light weight aluminum or titanium, job well. Others, like copper, are trickier because they conduct warm so effectively. Scientists are competing to address these difficulties, experimenting with new alloys and printing strategies. Every breakthrough opens doors to new applications– think printed batteries, heat-resistant engine components, and even room environments developed with lunar dust.

(can 3d printers print metal)

So next time you become aware of 3D printing, remember it’s not just about plastic toys and prototypes. Metal 3D printing is silently revolutionizing how we make things, blending the accuracy of computers with the raw power of metallurgy. It’s a tip that also the earliest products can discover new life in the electronic age.