Discover a professional 3D printing powder supplier

(How to Prepare Spherical Titanium Powder)

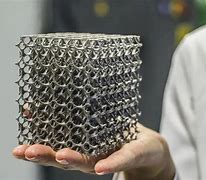

As an advanced lightweight and high-strength metal material, titanium has the

advantages of high specific strength, low density, excellent corrosion

resistance and good biocompatibility. It is widely used in aerospace, automobile

industry, chemical industry, biomedical and other fields. High-performance

spherical titanium powder has the characteristics of high sphericity, good

fluidity, high loose density, low oxygen content (<0.15%) and fine particle

size. It is mainly used in advanced powder metallurgy technology, laser additive

manufacturing technology, and thermal spraying technology.

At present, the main processes for preparing spherical titanium powder include gas atomization, plasma rotating electrode method, and radio frequency

plasma spheroidization.

Preparation of Spherical Titanium Powder by Gas Atomization

The gas atomization method is currently a more mature industrialized method

for preparing titanium powder. It uses high-speed airflow to break the metal

stream. Because this method only needs to overcome the bonding force between the

liquid metal atoms to make it dispersed, Has a good economy. The gas atomization

method is a method that uses high-speed inert gas to atomize the titanium metal

liquid, which is crushed and solidified to obtain spherical titanium powder. The

gas atomization method has the characteristics of low cost, high production

efficiency, high sphericity of titanium powder, low oxygen content and low

environmental pollution. The powder suitable for injection molding has only a

small proportion of particle size.

Preparation of Spherical Titanium Powder by Plasma Rotating Electrode

Method

The metal or alloy is made into a consumable electrode. The end of the

electrode is heated by an electric arc and melted into a liquid. The centrifugal

force of the high-speed rotation of the electrode throws the liquid out and

smashes it into fine droplets, and finally condenses it into a powder.

The plasma rotating electrode method has the following advantages: high

powder purity, no pollution, low oxygen content, simple process; long

spheroidization time of metal droplets, high powder sphericity, narrow particle

size distribution, and high fine powder yield; Compared with atomization, the

plasma rotating electrode method does not require high-speed gas flow, thus

avoiding hollow powder produced by the "umbrella effect". However, this method

has limitations: the electrode rod must be made into a rod of a specific size,

and the cost is high; the electrode rod is fixed-length, so the continuity of

atomization cannot be guaranteed, and the atomization efficiency is low; the

electrode speed is fast and high-speed The shaft is easy to wear during the

rotation, so how to maintain the vacuum tightness and cleanliness of the

high-speed rotating electrode is still a key issue.

Preparation of spherical titanium powder by radio frequency plasma

Because plasma has the characteristics of high temperature, high enthalpy,

high chemical reaction activity, and controllability of the reaction atmosphere

and reaction temperature, it has its unique advantages in the synthesis and

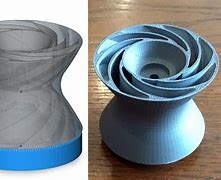

preparation of powder materials and the spheroidization treatment. The radio

frequency plasma spheroidization method uses the induction of radio frequency

electromagnetic field to inductively heat various gases to generate radio

frequency plasma, and uses high temperature plasma to melt non-spherical powder.

The molten powder particles are under extremely high surface tension under the

action of surface tension. Under the temperature gradient, it rapidly condenses

to form small droplets with high sphericity, thereby obtaining spherical

powder.

The advantages of the radio frequency plasma spheroidization method are that

it can increase the sphericity and better the fluidity of the powder; it can

eliminate the pores of the internal particles and increase the looseness of the

powder; it can appropriately change the particle morphology and improve the

purity of the powder. In addition, because the atmosphere in the plasma reactor

is controllable, the process is more conducive to the rapid and simple

preparation of high-purity spherical powders, and has a good industrial

prospect.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market. Our professional work team provides perfect solutions to

help improve the efficiency of various industries, create value, and easily cope

with various challenges. If you are looking for spherical titanium powder, please send an

email to:sales2@nanotrun.com

(How to Prepare Spherical Titanium Powder)