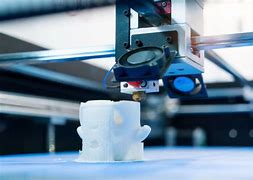

Discover a professional 3D printing powder supplier

(Titanium Alloy 3D Printing Powder has been Used in Aerospace and Other Fields)

The quality of metal additive manufacturing parts is closely related to the

characteristics of the metal powder, including the particle size, sphericity,

fluidity, and bulk density of the powder. The application requirements of

"high-precision", "high-quality" and "ultra-precision" in the aerospace,

aviation, medical and other fields also place higher requirements on the quality

of metal 3D printing powders.

Based on in-depth market observations and long-term metal additive

manufacturing practices, 3dprintingpassion has developed TA1, TA15, TC4, TA18, TC21 and

other titanium and titanium alloy powders in response to the special needs of

users for a long time, which have been successfully applied in aviation Additive

manufacturing fields such as aerospace.

The excellent comprehensive mechanical properties of TC4 can meet the needs

of aero-engines for powder performance. Its high specific strength and light

weight provide support for blade weight reduction; the powder has high thermal

stability and oxidation resistance, which can prolong the life of the blade.

Check the interval; at the same time, the hollow structure is adopted inside the

part, and the design space is large, which can realize more diversified shapes

and meet the needs of various scenes.

TC4 is a titanium alloy material widely used in the aerospace and medical

fields. After 3dprintingpassion TC4 powder is formed by selective laser melting (SLM)

additive manufacturing equipment, the microstructure of the obtained parts is

uniform and dense, and has the characteristics of rapid solidification. The

tensile strength, yield strength, and elongation of the printed parts are about

6~7%, 6~10%, and 55-60% higher than the index of forgings, respectively.

The antenna support structure has undergone topology optimization and

integrated integration design. Compared with traditional mechanical parts, the

weight of the antenna support is reduced by 35%, the stress concentration state

is relieved, and the peak stress response state is reduced by 6%. The internal

dimensional accuracy of the parts is high. The high specific strength and medium

high temperature mechanical properties of TA15 titanium alloy make the parts

have good bearing capacity and stress ability, which meets the requirements of

safety-critical applications such as aerospace.

TA15 is a high temperature titanium alloy powder with room temperature mechanical

properties slightly higher than TC4 and medium high temperature mechanical

properties. It is mainly used for the printing and forming of aerospace

structural parts and engine parts. 3dprintingpassion independently developed TA15 powder.

At present, the powder has been used in the forming of various types of titanium

alloy parts. The maximum size of the parts reaches 1000mm. Some products have

been successfully delivered to customers to meet the stringent requirements of

the aerospace industry.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for Ti6Al4V Powder, please send an email to:

sales2@nanotrun.com

(Titanium Alloy 3D Printing Powder has been Used in Aerospace and Other Fields)