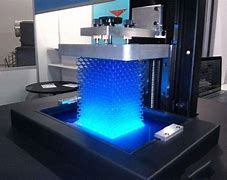

Discover a professional 3D printing powder supplier

(The Effect of Placement and Powder Reuse on the Fatigue Performance of 3D Printed Parts)

Previous studies have found that the fatigue performance of the parts made by

the repeated use of Ti6Al4V under the electron beam powder bed fusion process is

69 times lower than that of the parts made with the unused new powder. The

reason is that the particle surface oxidation leads to the internal fusion of

the parts. defect. In another study, the plasticity and toughness of

nickel-based alloy powders printed by a laser powder bed fusion process for

multiple cycles were reduced.

Taking into account the hypothesis that powder properties may affect the

quality of parts and the needs of industrial applications, the fatigue

performance of 3D printing materials (especially the ultra-high cycle fatigue

performance) has become one of the urgent scientific problems in the field of

additive manufacturing.

The change of powder characteristics and its influence on the effect of

spreading powder:

The powder used in the study is 17-4PH stainless steel, the initial powder

size distribution is between 15-45μm, and the initial quantity of 80kg is used

for 15 consecutive printing. Each time the manufacturing is completed, the

powder is sieved and thoroughly mixed with the unused powder. The effects of the

placement of the parts and the repeated use of powder on the tensile strength

and fatigue life of the parts are studied respectively.

A comprehensive study of materials such as IN718, Ti6Al4V, AlSi10Mg, etc. by

a number of units found that the repeated use of the powder will cause changes

in the characteristics of the powder, mainly as follows:

The fine powder content decreases, the particle size distribution narrows,

and the average particle size increases, especially for AlSi10Mg; the morphology

of the particles will also become more slender (found in some studies); compared

with the unused powder, the cycle has been Due to the disappearance of satellite

powder and long-term high temperature exposure, the moisture content of the

powder is reduced, the phenomenon of powder agglomeration is reduced, and the

fluidity is generally increasing.

The results of the particle size test in this study basically verified the

above conclusions. The particle size width of the initial powder was 45μm, and

the particle size of the 15th batch was 41μm. The particle size of the powder

has become narrower; the powder used repeatedly has smaller inter-particle gaps

than the initial powder. The powder fluidity and filling state are improved. In

general, the repeated use of powder can make spreading more uniform and reduce

the gap between particles. This change increases the complexity of understanding

how powder specifications affect part performance. At the same time, the change

of powder characteristics may bring some changes to the mechanical properties of

parts at different positions on the substrate.

The study of fatigue behavior found that the repeated use of powder has

almost no direct effect on the parts that have not been machined and have

printed surfaces, which is mainly due to the retention of surface roughness;

while for the machined samples, Under low-cycle and medium-cycle fatigue

conditions, continuous repeated use of powder will not affect the fatigue

behavior; however, under high-cycle fatigue conditions, the fatigue life of the

15th batch of samples is significantly higher than that of the first batch. The

study on the fatigue life of the left and right samples found that the fatigue

life of the right sample is higher than that of the left sample, but this gap

will still decrease with the increase in the number of powder usage.

About 3dprintingpassion:

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for 17-4PH Powder, please send an email to:

sales2@nanotrun.com

(The Effect of Placement and Powder Reuse on the Fatigue Performance of 3D Printed Parts)