Discover a professional 3D printing powder supplier

(The Influence of Magnetic Field-assisted Wire Material Additive Manufacturing on the Structure and Properties of In625 Superalloy)

Magnetic field assisted wire additive manufacturing of In625 superalloy was

used to study the influence of magnetic field on the microstructure and

performance. The mechanism of the influence of magnetic field on the

microstructure was discussed. The application of magnetic field can improve the

mechanical properties of wire additive manufacturing of 625 alloy. .

Because of its high deposition efficiency, low cost and flexible

manufacturing, wire material for additive manufacturing has been widely used in

the manufacturing of In 625 superalloy. However, higher heat input and severe

element segregation occurred during the additive manufacturing process, which

reduced the quality of the formed In625 alloy and reduced its service

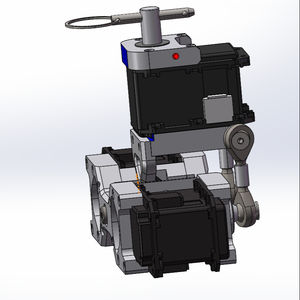

performance. Here, a magnetic field is used to assist in the process of additive

manufacturing of In625 from cold metal transition wires to change its

microstructure. The influence of the magnetic field on the microstructure and

mechanical properties of CMT-WAAM (Cold Metal Transition-Wire Additive

Manufacturing) was studied.

The results show that the stirring effect of the magnetic field plays a role

in the grain refinement during the deposition process; the convection caused by

the magnetic field promotes the diffusion of elements, such as Nb and Mo, in the

molten pool, thereby inhibiting the segregation of elements. The mechanical

properties of In625 alloy deposited with magnetic field assisted deposition

showed that the microhardness increased, the yield strength increased by about

13%, and the ultimate tensile strength and toughness increased. Based on the

above work, it is very obvious that the applied magnetic field in the CMT-WAAM

process refines the dendrites, suppresses element segregation, and effectively

improves the performance of the deposited IN625 alloy.

In the current research, the In625 alloy is manufactured using WAAM under the

condition of an external constant magnetic field. The unique feature of this

work is that the magnetic field is applied during the directional solidification

of the alloy (that is, during the WAAM manufacturing process). The feasibility

of magnetic field stirring to improve the microstructure and mechanical

properties of the In625 alloy manufactured by WAAM was also demonstrated.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for Inconel625 powder, please send an email to:

sales2@nanotrun.com

(The Influence of Magnetic Field-assisted Wire Material Additive Manufacturing on the Structure and Properties of In625 Superalloy)