Discover a professional 3D printing powder supplier

(Research Progress of Laser Powder Bed Melting Forming Inconel625 Nickel-based Alloy)

Additive manufacturing, also known as 3D printing, is an advanced

manufacturing technology developed in the past 30 years. In theory, additive

manufacturing technology can transform any CAD model into a physical entity,

which greatly increases the geometric design freedom and manufacturing

capabilities of complex parts.

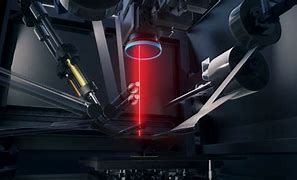

For metals, laser powder bed melting (LPBF) mainly uses high-energy laser

beams to melt preset thin layers of metal powder layer by layer, which can form

high-performance parts after solidification and cooling. It is one of the most

promising additive manufacturing technologies. one. This technology is

especially suitable for the forming and processing of small-batch,

high-precision, personalized, and complex structure parts, and has a wide range

of application prospects in the fields of aerospace, biomedicine, automobiles,

and abrasive tools.

Most of the Ni-based alloys formed by LPBF have obvious anisotropy, most of

the grains grow along the <100> direction, and a large number of fine

grains are distributed at the boundary of the molten pool, and the texture

presents a typical {100}<001> type Cube texture. The grain growth

direction of the formed part is closely related to the scanning strategy. When

the cross scanning method is adopted, the fastest grain growth direction

<100> is perpendicular to the forming substrate; when the unidirectional

scanning is adopted, the grain growth direction is 60% to the forming direction.

When the laser point light source moves, the heat flow direction is not

completely symmetrical to the growth direction.

Inconel 625 (IN625) is a nickel-based superalloy, which mainly uses the solid

solution strengthening effect of elements such as molybdenum (Mo) and niobium

(Nb) in the Ni-Cr matrix to obtain high-temperature strength and creep

resistance. The corrosion resistance and solderability in the environment are

also good. However, because of its high hardness, low thermal conductivity and

high work hardening rate, IN625 is considered to be an alloy that is difficult

to process or is difficult to manufacture from subtractive materials. During the

machining process, the machine tool wears quickly, and this material Or it is

difficult to control its performance during forging.

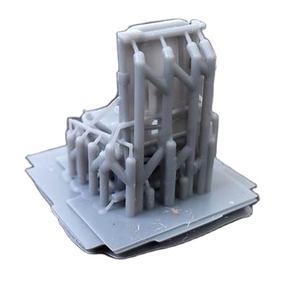

Characterize the macroscopic defects and microstructures of IN625 alloy

as-cast and post-treatment, and deeply explore the formation mechanism of

macroscopic defects (pores, microcracks, spheroidization, unmelted zone) and the

evolution mechanism of microstructure (grain boundaries, second Phase,

dislocation, sub-grain boundary, stacking fault, etc.)

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for Inconel625 powder, please send an email to:

sales2@nanotrun.com

(Research Progress of Laser Powder Bed Melting Forming Inconel625 Nickel-based Alloy)