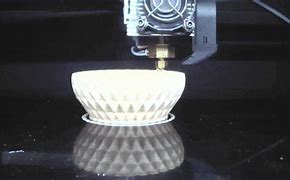

Discover a professional 3D printing powder supplier

(The Main Disadvantages of Stainless Steel Powder Metallurgy)

Compared with stainless steel produced by traditional smelting process,

stainless steel powder metallurgy has the advantages of producing parts close to

net shape, high dimensional accuracy, high material utilization, and uniform

structure. However, it does not mean that stainless steel powder metallurgy

products are perfect. Stainless steel powder metallurgy also has its

disadvantages.

Most of the injection molding defects of stainless steel powder metallurgy

products are in the injection molding process. Some defects of injection molding

are visible to the naked eye, some may appear in the subsequent desorption or

sintering process, but they can also be traced back to the injection molding

process. Therefore, the quality control of stainless steel powder metallurgy

products is very important.

The defects of stainless steel powder metallurgy products are generally

manifested in injection molding plate defects: flashing, foaming, corrugated

surface, laminar or skin, depression and surface black spot deformation are

observed in appearance, low green strength, mold pasting operation. The causes

and influencing factors of these defects are different, among which injection

temperature and injection pressure are the key factors.

By adjusting the injection temperature and injection pressure, most defects

can be solved. When the temperature and pressure are adjusted to some defects,

it is the correct choice to further trace the binder system, the uniformity of

powder and jointing agent mixing and refining, whether the feed is polluted,

moisture absorption, humidity and other factors, and the mold cavity should be

checked. Body design, gate, shunt channel and gate design are reasonable.

In the normal operation of injection molding and high-quality injection

molding briquette, many influencing factors have been continuously explored and

summarized in practice, accumulated experience, compared the problem with

accurate analysis and judgment, and adjusted in time.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for SS316L powder, please send an email to:

sales2@nanotrun.com

(The Main Disadvantages of Stainless Steel Powder Metallurgy)