Discover a professional 3D printing powder supplier

(Energy Efficiency: Measuring the Power Consumption of 3D Printers)

How Much Juice Does Your 3D Printer Really Use? Unplugging the Truth About Power Consumption

(Energy Efficiency: Measuring the Power Consumption of 3D Printers)

3D printers are cool. They make toys, tools, and even tiny dinosaurs. But have you ever wondered how much electricity these machines gobble up while doing their magic? Let’s talk about power consumption—because even robots need to pay the electric bill.

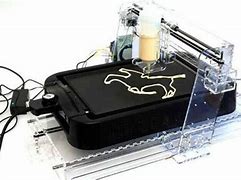

First, think about your kitchen blender. When you press “on,” it roars to life, spins wildly, and uses a burst of energy. A 3D printer works differently. It hums quietly for hours, heating up parts and moving motors bit by bit. But does that mean it’s sipping power like a polite guest or chugging it like a thirsty marathon runner?

To find out, you need to measure. Plug your printer into a watt-meter—a cheap gadget that tracks electricity use. Let’s say you’re printing a plastic vase. The meter will show spikes when the printer heats its nozzle or bed. Once it’s hot, the power drops to a steady trickle. Over six hours, a typical desktop 3D printer might use as much energy as running a microwave for 30 minutes. Not too bad, right? But numbers add up. Print nonstop for a month, and your printer could cost more than your coffee habit.

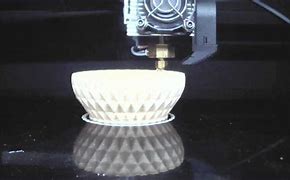

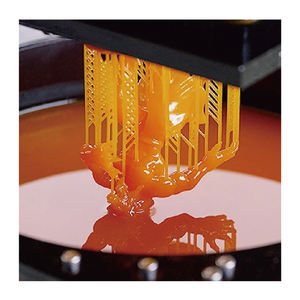

Not all printers are the same. Bigger machines with heated chambers for fancy materials? They’re energy hogs. Smaller ones that print basic plastics? Lightweights. Settings matter too. Cranking up the nozzle temperature or printing faster forces the machine to work harder. It’s like revving a car engine while stuck in traffic—wasted fuel.

Filament type also plays a role. PLA, a common plastic, melts at lower temps. ABS or nylon need more heat, so the printer guzzles power longer. Ever tried printing with carbon fiber blends? Your printer will sweat bullets, and your wallet might too.

Here’s a real-world example. Print a set of chess pieces. A standard printer might use 0.1 kWh, costing pennies. But if you’re printing a life-sized replica of a medieval sword, expect that number to jump. Multiply this by a classroom or small factory with 20 printers running 24/7, and suddenly you’re talking real money.

How do you save energy? Preheat manually. Lots of printers sit idle at max heat, waiting for you to hit “start.” Use standby modes or timers. Print during off-peak hours if your utility company charges less at night. Pick efficient filaments. And maybe don’t print that 10-pound statue of your cat unless you really need it.

Big companies are already on this. Some industrial printers now recycle heat or use smarter software to cut power use by 30%. Home users can tweak settings in free programs like Cura to slow down prints or lower temps without ruining quality.

(Energy Efficiency: Measuring the Power Consumption of 3D Printers)

Energy efficiency isn’t just about saving the planet. It’s about saving cash. A few small changes can keep your projects affordable—and keep your printer from becoming that sneaky appliance that jacks up your bill. So next time you hit “print,” remember: every watt counts. Even tiny plastic dinosaurs deserve an energy-efficient birth.Inquiry us if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com) hot tags: 3d printing,3D printiner,3d printing material

(Energy Efficiency: Measuring the Power Consumption of 3D Printers)