Spherical element powders are specialized materials designed for use in various 3D printing technologies, particularly those involving Powder Bed Fusion (PBF) methods such as Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS). These powders consist of small, uniformly shaped spherical particles that offer several advantages over irregularly shaped powders. The spherical shape promotes better flowability, packing density, and layer uniformity, which are critical for achieving high-resolution prints with consistent mechanical properties.

Optimized Flowability: Spherical particles flow smoothly and consistently, reducing the risk of clogging during powder dispensing and improving print reliability.

Uniform Layer Thickness: The regular shape ensures even distribution and compaction of layers, leading to more accurate and precise printed parts.

Enhanced Packing Density: Spheres fit together more closely than irregular shapes, resulting in higher green density before sintering or melting, which translates to denser and stronger final parts.

Reduced Porosity: Uniform layers and high packing density minimize the occurrence of voids and pores in the printed object, improving overall part quality.

Better Surface Finish: Spherical powders contribute to a smoother surface finish on the final product due to the reduced likelihood of surface irregularities caused by powder geometry.

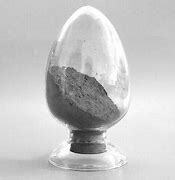

(Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder)

The details of your specific request for metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder are as follows: * Polymorphism: High purity can be achieved by using high-quality raw materials and strict quality control processes. * Particle size distribution: The size distribution of the particles can affect the physical properties of the powder, such as its porosity, strength, and. For example, particles with a larger diameter tend to have a higher porosity, while those with a smaller diameter tend to be harder. * Chemical composition: The chemical composition of the powder can also affect its physical properties. For example, the presence of impurities or dopants can modify the particle size distribution and other properties. * Printability: The printability of the powder depends on several factors, including the type of 3D printer being used, the feedstock used, and the operating conditions. It is important to optimize these parameters to achieve good print results. In general, achieving high purity and good printability requires careful consideration of the various factors that affect the powder's properties. It may also require multiple experiments and iterations to find the optimal parameters for your specific application.

(Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder)

Aerospace: Precision parts requiring high strength-to-weight ratios, like turbine components and satellite parts, benefit from the consistency and performance offered by spherical metal powders.

Medical Devices: SLS and DMLS of biocompatible materials like titanium for implants and surgical instruments rely on spherical powders for accuracy and surface quality.

Dental Prosthetics: Custom-made crowns, bridges, and implants are produced using spherical powders for their precise fit and finish.

Automotive: Rapid prototyping and low-volume production of engine parts, lightweight structures, and intricate components leverage spherical powders for their efficiency and design flexibility.

Jewelry: Complex, detailed jewelry designs are realized through the use of high-detail resins or metal powders that can achieve fine details and a smooth finish.

Company Profile

Kmpass is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Q: Is Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder more expensive than irregular-shaped powders? A: Typically, yes. The production process for spherical powders involves advanced atomization techniques to ensure uniformity, which can increase costs compared to irregular powders.

Q: Can Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder be recycled for repeated use in 3D printing? A: Yes, unused powder can often be collected, sieved to remove contaminants and particles outside the desired size range, and then reused in subsequent prints.

Q: Does Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder improve print speed in 3D printing processes? A: While it doesn't inherently speed up the printing process, their optimized flowability and layer uniformity can reduce the need for rework and post-processing, ultimately saving time.

Q: Is Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder available for both plastic and metal 3D printing? A: Yes, Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder is used in both plastic (polymer-based) and metal 3D printing, with different compositions tailored to each technology and application.

(Metal spherical nickel powder high purity 3D printing spherical nickel powder elemental Ni powder)