Discover a professional 3D printing powder supplier

Why Choose 3dprintingpassion?

KNOW MORE ABOUT US

As a leader in industrial innovation 3dprintingpassion has an expansive inventory that includes a wide range of 3d printing powder products and materials. The products of 3dprinting passion are used throughout automotive, mechanical engineering, manufacturing, mining, chemical, and even aerospace industries.

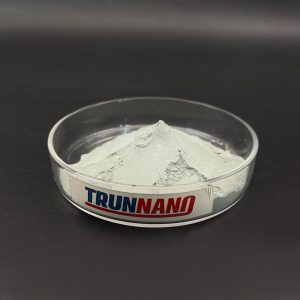

SHOP BY CATEGORIES

Designed by artists, made by us, just for you.

BEST SELLER

FEATURED PRODUCTS

CUSTOMER REVIEWS

Words from Satisfied Shoppers

Latest News