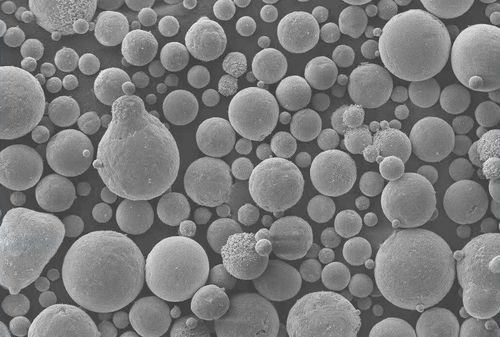

Aluminum-based 3D printing powders are specialized materials designed for use in additive manufacturing processes, specifically for Powder Bed Fusion (PBF) techniques such as Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS). These powders are composed primarily of aluminum, often alloyed with elements like silicon, magnesium, or titanium to improve their mechanical and processing properties. They are gaining popularity due to their lightweight nature, good thermal conductivity, and potential for high geometric complexity in a wide array of applications.

Lightweight: Aluminum is known for its low density, making aluminum-based 3D printed parts ideal for applications where weight reduction is crucial, such as in aerospace and automotive sectors.

Thermal Conductivity: These powders facilitate the production of parts with excellent heat dissipation properties, useful in heat sinks and other cooling systems.

Strength and Ductility: When alloyed correctly, aluminum powders can result in printed parts with a balance of strength and ductility, suitable for functional and structural components.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer, providing inherent corrosion resistance to the printed parts.

Design Freedom: The 3D printing process allows for the creation of complex geometries and lattice structures, taking advantage of aluminum's properties to produce lightweight yet strong components.

(High Precision Aluminum Die Casting Parts Die Casting Product)

The high precision aluminum die casting parts produced by our company can meet the requirements of a wide range of customers in various industries, such as electronics, machinery, automotive, and aerospace. The following parameters of the high precision aluminum die casting parts are typically included: 1.Die shape: The die shape is the specific configuration of the part to be manufactured. It should be accurate to within a certain tolerance. 2.Die size: The die size refers to the width and height of the part to be cast. This can vary depending on the specific application. 3.Casting temperature: The casting temperature determines the phase behavior of the metal during the casting process. A higher temperature will produce a harder material, while a lower temperature will produce a softer material. 4.Casting pressure: The casting pressure affects the way the metal flows during the casting process. It must be carefully controlled to ensure that the part is produced accurately and with minimal distortion. 5.Casting material: The material used for the casting should be compatible with the part being cast. If there are any compatibility issues, it may be necessary to use a different material. 6.Casting method: The casting method involves the process of injecting molten metal into a mold to create a desired part. Different methods may be appropriate for different types of parts or materials. 7.Casting quality control: To ensure that the high precision aluminum die casting parts are of high quality, regular testing and inspection procedures should be implemented. Overall, the high precision aluminum die casting parts produced by our company meet the needs of a wide range of customers by providing accurate, high-quality parts with minimal distortion and distortion.

(High Precision Aluminum Die Casting Parts Die Casting Product)

Aerospace: Lightweight structural components, satellite parts, and aerospace fixtures benefit from aluminum's strength-to-weight ratio and design flexibility.

Automotive: Prototypes, lightweight chassis components, and intricate engine parts are being developed using aluminum-based powders to reduce vehicle weight and increase fuel efficiency.

Racing and Sports Equipment: Bicycle frames, automotive racing parts, and sports gear aluminum’s lightweight and durable properties to enhance performance.

Tooling and Fixtures: Complex, custom tooling and fixtures can be rapidly produced with aluminum powders, improving manufacturing efficiency and reducing costs.

Electronics: Heat sinks and enclosures in electronic devices take advantage of aluminum's thermal conductivity and lightweight nature.

Company Profile

Kmpass is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Q: Is High Precision Aluminum Die Casting Parts Die Casting Product as strong as traditionally manufactured aluminum parts? A: Depending on the alloy and printing parameters, 3D printed aluminum parts can achieve similar or, in some cases, improved mechanical properties compared to traditionally cast or machined parts, especially when leveraging the design advantages of AM.

Q: What are common challenges in printing with High Precision Aluminum Die Casting Parts Die Casting Product? A: Challenges include managing high thermal conductivity leading to uneven heating and cooling, potential for hot cracking, and ensuring consistent powder bed quality to avoid porosity.

Q: Can High Precision Aluminum Die Casting Parts Die Casting Product be recycled? A: Yes, unused or unsintered powder can typically be collected, sieved, and reused in subsequent prints, contributing to sustainability efforts.

Q: How does the cost of aluminum 3D printing compare to traditional methods? A: While initial setup and material costs can be higher, aluminum 3D printing offers cost savings through reduced waste, faster prototyping, and the ability to produce complex parts in lower volumes more efficiently.

(High Precision Aluminum Die Casting Parts Die Casting Product)