Discover a professional 3D printing powder supplier

(Batch Application of 3D Printing Aluminum Alloy Powder)

High-quality spherical metal powder is an important guarantee for

high-performance metal additive manufacturing. Its composition, oxygen content

and powder physical properties (morphology, particle size distribution, powder

fluidity, loose density, etc.) have an impact on the stability and manufacturing

process of 3D printing. The physical and chemical properties of the parts are

very important, affecting and determining whether the product can be installed

and applied.

Among the many technical indicators of powder, the sphericity of the powder

and the ratio of satellite spheres directly affect the fluidity and bulk density

of the powder. Low powder sphericity or too high proportion of satellite spheres

will directly affect the powder feeding or spreading quality, which in turn

affects the quality of printed parts, and produces internal and surface defects.

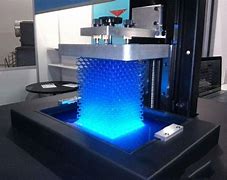

In recent years, with the increasing maturity of additive manufacturing

technology, the demand for efficient forming of complex components and large

parts has become higher and higher. Smart additive manufacturing factories have

also emerged, but they are limited by the bottom-mounted powder supply mode in

equipment operation. In the process, it is impossible to add powder online, and

the opening and adding powder is prone to step connection and metallurgical

defects. Therefore, the international mainstream large-size equipment usually

adopts the continuous powder feeding system of the upper feeding type. The upper

powder feeding method requires high powder fluidity. If the powder fluidity is

not good and the powder falls unevenly, or there is agglomeration or unevenness

in the powder spreading process, the printing quality will be adversely

affected. In the future, the demand for high fluidity powders in metal additive

manufacturing will become more and more prominent.

Aluminum alloy powder is not easy to obtain high fluidity due to its light

density, and the morphology control of the preparation of aluminum alloy powder

is more difficult than other alloy materials, so that for a long period of time,

the aluminum alloy powder for 3D printing only has an angle of repose. Evaluate

powder fluidity, but can not be directly measured with a Hall flow meter. In

2020, 3dprintingpassion launched a series of high-fluidity aluminum-based alloy powder

materials optimized for metal additive technology. The powder has high

sphericity and good fluidity, which further breaks through the poor fluidity and

low loose density of aluminum alloy powders in the past. And other technical

problems. At present, the company's high-fluidity aluminum-based alloy powder

materials (AlSi10Mg, etc.) have been used in aerospace, automotive and

transportation fields in batches, and the powder product characteristics and

printed parts have good performance.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for AlSi10Mg powder, please send an email to:

sales2@nanotrun.com

(Batch Application of 3D Printing Aluminum Alloy Powder)