Discover a professional 3D printing powder supplier

(Industrial Insights: Who Relies on Large-Scale 3D Printers?)

**Printing the Future: The Big Players Behind Giant 3D Printers**

(Industrial Insights: Who Relies on Large-Scale 3D Printers?)

Imagine machines that can spit out car parts, airplane wings, or even entire houses. This isn’t science fiction—it’s happening right now. Large-scale 3D printers are reshaping industries in ways that feel almost magical. But who’s actually using these massive machines? Let’s dive into the world of oversized printers and the sectors betting big on their potential.

First up: aerospace. Companies like Boeing and Airbus are turning to giant 3D printers to create lightweight parts for planes. Traditional manufacturing often involves carving metal blocks, which wastes material. With 3D printing, they build parts layer by layer, using only what’s needed. This cuts costs and makes planes lighter, saving fuel. Even NASA uses these printers to make rocket components. When every gram matters in space, 3D printing is a game-changer.

Next, the automotive industry. Car manufacturers love speed. Designing a new prototype used to take months. Now, companies like Ford and BMW use industrial 3D printers to test parts in days. Need a new gearbox housing? Print it overnight. Custom tools, brackets, even entire chassis sections come to life faster than ever. Electric vehicle startups are especially hooked. They use these printers to experiment with designs that older factories can’t handle.

Construction is another surprise player. Yes, buildings. Firms like ICON in Texas print entire homes using concrete-spewing printers. These machines work around the clock, stacking walls in hours instead of weeks. It’s not just for houses, either. Bridges, office complexes, and emergency shelters are popping up worldwide. The goal? Faster, cheaper builds with less labor. In disaster zones, 3D-printed shelters can be lifesavers—quick to make, sturdy, and adaptable.

Healthcare might seem unlikely, but it’s all in. Hospitals and labs use large 3D printers for custom prosthetics and implants. A child missing a hand can get a colorful, functional replacement printed in a day. Surgeons practice on 3D-printed replicas of patient organs before complex operations. Dental clinics print crowns and bridges on-site, skipping wait times for labs. The tech even extends to bioprinting—research labs experiment with printing living tissues. While still early, the idea of printing skin or cartilage is inching closer to reality.

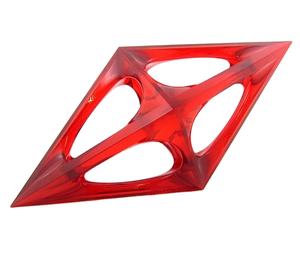

Then there’s the entertainment industry. Movie studios and theme parks use giant printers for props and set pieces. Need a 15-foot dragon statue for a film? Print it in pieces, glue it together, paint it. Theme parks create massive sculptures and ride components without hand-carving every detail. It’s faster, cheaper, and lets designers dream bigger. Even fashion designers are playing with 3D-printed accessories—think wild, geometric shoes or futuristic jewelry.

Energy companies are jumping in too. Oil, gas, and wind energy firms print custom parts for pipelines, turbines, and drills. These parts often face extreme conditions—heat, pressure, corrosion. 3D printing allows for complex, durable designs that traditional methods struggle with. Offshore wind farms, for example, use printed turbine blades designed to withstand harsh ocean weather.

Smaller businesses aren’t left out. Startups and workshops use rented or shared industrial printers to compete with bigger players. A local bike shop might print custom frames. Artists create massive installations. Schools and universities teach students to design for 3D printing, preparing the next gen of engineers.

(Industrial Insights: Who Relies on Large-Scale 3D Printers?)

The magic of large-scale 3D printing isn’t just about size. It’s about flexibility. Need a one-off part? No problem. Want to tweak a design? Just update the file. Industries stuck in the “we’ve always done it this way” mindset are waking up. From rockets to race cars, the race to print bigger, better, and faster is on. The question isn’t “who uses these printers?” anymore—it’s “who isn’t?”Inquiry us if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com) hot tags: 3d printing,3D printiner,3d printing material

(Industrial Insights: Who Relies on Large-Scale 3D Printers?)