Discover a professional 3D printing powder supplier

(Jerk Jargon: Troubleshooting Jerky Movements in Your 3D Printer)

Title: When Your 3D Printer Dances the Robot: Fixing Jerky Moves Like a Pro

(Jerk Jargon: Troubleshooting Jerky Movements in Your 3D Printer)

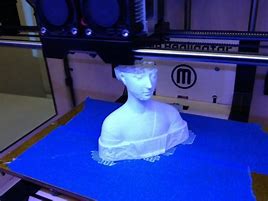

Your 3D printer is supposed to glide smoothly, right? But sometimes it starts jerking around like it’s doing the robot at a disco. Annoying. Worse, those shaky moves can ruin prints. Let’s figure out why your printer’s throwing a tantrum and how to calm it down.

First, check the basics. Loose screws or belts can turn your printer into a wobbly mess. Tighten everything. Belts should feel like a guitar string—snug but not too tight. Loose parts? They’ll rattle and shake. Grab a screwdriver and go over the frame, motors, and rods. Even a tiny wiggle can mess things up.

Next, look at speed. Printing too fast? Your printer might slam into corners or sudden direction changes. Think of it like driving a car. If you floor it around a bend, you’ll skid. Lower the print speed in your slicer settings. Try 50 mm/s instead of 80. Slow and steady wins the race.

Then, there’s acceleration. This controls how quickly the printer speeds up or slows down. High acceleration forces the motors to jerk into motion. Dial it down. Start with 500 mm/s² for X and Y axes. Test. Adjust until movements smooth out.

Also, check “jerk” settings. No, your printer isn’t being rude. Jerk here means how fast it changes direction. Too high, and the print head lurches like it’s on a caffeine rush. Set jerk between 8-15 mm/s. It’s a sweet spot for most printers.

Filament issues can cause chaos too. Tangles or friction in the spool make the extruder tug unevenly. Make sure the filament unwinds smoothly. Clean the extruder gears. Gunked-up gears slip, causing uneven feeding. A quick brush with a toothpick or small wire brush helps.

Another culprit? Software glitches. Corrupted files or outdated firmware can confuse your printer. Re-slice the model. Save it again. Update your printer’s firmware if needed. Sometimes, a fresh start fixes everything.

Overheating motors might be the problem. Touch the motor after a print. If it’s too hot to hold, it’s struggling. Reduce motor current in the printer’s settings. Check the manual for safe limits. Motors should be warm, not scorching.

Lubricate the rods and rails. Dry spots make movement rough. Use a light machine oil or specific 3D printer grease. Wipe off excess. Too much oil attracts dust. A tiny drop on each rod does the trick.

Check the voltage on stepper drivers. If it’s too low, motors stutter. Too high, they overheat. Use a multimeter to test. Adjust the potentiometer on the driver board. Small tweaks matter. Half a volt can make a big difference.

Still stuck? Watch the printer mid-print. See where the jerking happens. Is it during curves? Sharp corners? Infill patterns? Adjust settings for those specific moves. Sometimes, turning down infill speed or outer wall speed helps.

Test with a simple calibration print. A small cube or benchy boat can reveal issues. Watch how layers go down. Tweaking settings one by one helps pinpoint the problem. Patience pays off.

(Jerk Jargon: Troubleshooting Jerky Movements in Your 3D Printer)

Remember, every printer’s different. What works for one might not work for another. Trial and error is part of the game. Keep notes. Track changes. Soon, you’ll crack the code and turn those robotic spasms into smooth, clean prints. Happy printing!Inquiry us if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com) hot tags: 3d printing,3D printiner,3d printing material

(Jerk Jargon: Troubleshooting Jerky Movements in Your 3D Printer)