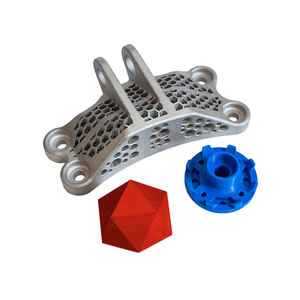

Discover a professional 3D printing powder supplier

(Precision Printing: Can You Print Smaller Than Your Nozzle Allows?)

**Squeezing Out the Impossible: How to Print Tiny Stuff with a Big Nozzle**

(Precision Printing: Can You Print Smaller Than Your Nozzle Allows?)

3D printing feels like magic. You dream up a design, hit “print,” and watch layers of plastic turn into something real. But here’s a question that bugs makers: can you print details smaller than your nozzle’s size? Let’s say your nozzle is 0.4mm wide. Common sense says you can’t print anything thinner than that. Turns out, common sense might be wrong.

First, know your nozzle. It’s the metal tip that squirts melted filament. Its width decides how thick each line of plastic is. A 0.4mm nozzle makes 0.4mm lines. Simple, right? But what if you need a 0.2mm detail? Do you swap nozzles? Maybe not.

Printers work by stacking layers. Layer height matters. Even with a 0.4mm nozzle, you can set layers as thin as 0.1mm. Thinner layers mean finer details vertically. Think of it like building a sandcastle. A big shovel makes thick layers, but a tiny spoon carves delicate shapes. Your nozzle is the shovel, but layer height is the spoon.

Horizontal details are trickier. A 0.4mm nozzle can’t squirt a 0.2mm line. Or can it? Speed matters. Print slower, and the plastic oozes less. The line gets narrower. It’s like squeezing toothpaste. Press hard, and a thick blob comes out. Press gently, and you get a thin strip. Some printers tweak flow rates mid-print, thinning lines for small details.

Temperature plays a role. Hotter filament flows easier. Cooler filament stays stiff. Lower the temperature, and the plastic doesn’t spread as much. This helps keep lines tight. But go too cold, and the filament jams. It’s a balancing act.

Material choice changes things. PLA is forgiving. ABS shrinks as it cools. PETG is sticky. Flexible filaments like TPU stretch. Some materials hold shape better, letting you push limits. Specialty filaments with fine particles (like carbon fiber) can print sharper details. They’re less gooey, so lines stay crisp.

Software tricks help too. Slicing programs let you adjust settings for specific parts. Maybe print outer walls slower and hotter for precision, while inner layers go fast and rough. Variable layer heights focus detail where it matters. Imagine a miniature statue. The face gets thin layers. The base uses thick ones.

Then there’s post-processing. Sanding, acetone vapor, or UV resin can smooth surfaces and sharpen edges. A rough print might look messy, but a little cleanup hides the nozzle’s limits.

But why bother? Swapping nozzles takes minutes. A 0.2mm nozzle exists. True. But changing nozzles means recalibrating. Z-offset, bed leveling, flow settings—it’s a hassle. Plus, tiny nozzles clog easily. Dust, burnt filament, or a misaligned feeder can ruin a print. Sticking with one nozzle saves time and frustration.

Some printers can’t switch nozzles. Closed systems or budget models lock you into default parts. Hacking the software or tweaking settings becomes the only way to improve.

Experiments show it’s possible. Makers have printed text smaller than 1mm with standard nozzles. Intricate gears, tiny figurines, even micro-scale jewelry. The key is patience. Slow prints, careful tuning, and accepting that some fails are part of the process.

Does this mean nozzle size doesn’t matter? No. A 0.4mm nozzle won’t match a 0.2mm nozzle’s precision. But it’s not a hard wall. With clever settings, material picks, and a bit of stubbornness, you can squeeze out details that seem impossible.

(Precision Printing: Can You Print Smaller Than Your Nozzle Allows?)

Next time someone says “your nozzle’s too big,” smile. Then show them a print that proves them wrong.Inquiry us if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com) hot tags: 3d printing,3D printiner,3d printing material

(Precision Printing: Can You Print Smaller Than Your Nozzle Allows?)