Discover a professional 3D printing powder supplier

(Properties and Applications of Titanium Alloy Powder)

What is titanium alloy powder?

Titanium alloy powder is the use of atomization, rotating electrode or vacuum

decompression atomization of qualified titanium alloy liquid metal into powder,

hot extrusion into rods, hot isostatic pressing into titanium alloy turbine

disk, aircraft keel joint, seawater desalination device Made of material.

Titanium and its alloys have high specific strength, good mid-temperature

thermal strength, corrosion resistance and rich resources, so they are widely

used in aviation, chemical industry, metallurgy, medical treatment, marine

engineering and other fields. Titanium and its alloys have become the mainstay

of aircraft engines. Metal structural materials.

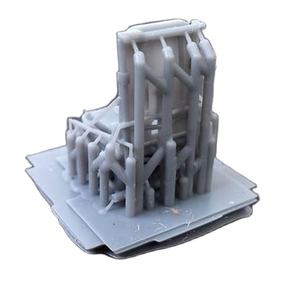

Sintering of titanium alloy powder

The sintering of titanium alloy powder is usually a solid phase diffusion

method. When the titanium alloy is prepared by the mixed element method, it is

found that the alloy elements in the titanium alloy will appear transient liquid

phase or provide diffusion channels during sintering to promote the

densification process, which is also called strengthened sintering.

The realization of the enhanced sintering process depends on three basic

conditions, namely the solubility criterion, the segregation criterion and the

diffusion criterion. Generally, the matrix should have a large solubility in the

additive or form an intermediate compound, while the solubility of the additive

in the matrix should be small. This is mainly due to: the low solubility of the

additive in the matrix will cause the additive to precipitate at the interface

between the powder particles , Which is conducive to the diffusion of the

matrix; the low solubility of additives in the matrix can reduce the amount of

additives needed to maintain enhanced sintering. Moreover, the densification

process of enhanced sintering is the process of diffusion of the matrix to the

additives, and this diffusion is conducive to the rapid growth of the sintering

neck and the elimination of pores. If the solubility of the additive in the

matrix is large, the diffusion opposite to the former will occur, the

Kirkendall effect will appear, the porosity will increase, and the sintered body

will expand.

Secondly, the additives can be precipitated at the interface between the

powder particles during the sintering process, and can be maintained throughout

the sintering process. This precipitation makes the diffusion interface between

the powder particles enriched with additives. Therefore, a channel for rapid

diffusion of the matrix is provided. The characteristic reaction of this

precipitation is that the liquidus and solidus continue to drop on the phase

diagram of the matrix and the added elements. When the solubility standard and

the precipitation standard are met, the enhanced sintering effect of the

additive depends on its influence on the diffusion rate of the matrix material.

The faster the material diffusion rate, the better the enhanced sintering

effect.

Application of titanium alloy powder

(1) Corrosion-resistant general parts are manufactured from treated pure

titanium sponge powder through cold pressing-vacuum sintering. The aviation

industry uses titanium powder sintered parts to become quite mature. Pure sponge

titanium powder or alloy powder is directly rolled into porous titanium or dense

titanium plate. The former can be coiled and welded into a porous tube for use

as a filter.

(2) Titanium powder and aluminum powder are used as raw materials to produce

TiAI alloy targets by sintering elemental powders. In the electronic field, it

is required to use titanium getter materials that can reach a high degree of

vacuum. Usually, HDH titanium powder with a large surface area is used to

produce this kind of getter materials.

(3) Titanium alloy powder is badly formed by cold isostatic pressing and

vacuum sintering, and then forged or rolled to obtain various profiles. Such

titanium alloy profiles have a wide range of uses.

(4) Pre-alloyed powder HIP is directly formed to produce high-strength

titanium alloy products.

(5) Pre-alloyed powder is directly HIP formed into parts, which are used for

parts of mid-temperature aeroengines or reheated addition materials to HIP

billets to manufacture load-bearing components for aircraft.

(6) Engine connecting rods produced by hot isostatic pressing after element

mixing and vacuum sintering are widely used in automobile engines, and powder

metallurgical intake and exhaust valves are also very common in the automobile

industry.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for Ti6Al4V Powder, please send an email to:

sales2@nanotrun.com

(Properties and Applications of Titanium Alloy Powder)