Discover a professional 3D printing powder supplier

(Small Titanium Powder of Tens of Microns Can Print Key Parts of Aviation)

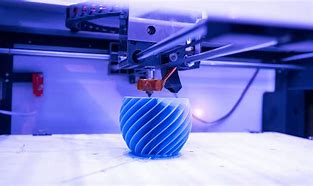

In recent years, 3D printing has become a hot technology that has attracted

much attention. It uses "printing materials" such as plastics and metals to be

manufactured into physical objects by stacking and printing layer by layer, and

its application fields are becoming more and more extensive. Among many

"printing materials", metal powder materials have huge advantages and

development prospects. Among them, spherical titanium and titanium alloy powders

for 3D printing used in aviation, aerospace, and medical equipment have always

been manufactured due to extremely high technical difficulties.

Titanium metal has the characteristics of light weight, high strength, and

corrosion resistance. In recent years, with the development of global 3D

printing technology, seemingly unremarkable titanium and titanium alloy powders

have become key materials required in the field of 3D printing of metal parts.

3D printing is a very comprehensive industry, involving multiple disciplines,

including metallurgy, chemical engineering, materials, etc. The research and

development process is very difficult, and it can only be developed, explored,

and adjusted. The biggest advantage of 3D printing is that there is no need to

open molds. Some complex products, such as special-shaped parts and structural

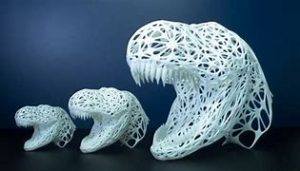

parts, can be directly realized through 3D printing. At present, titanium and

titanium alloy spherical powder products are mainly used in aviation, aerospace,

medical equipment, biomedicine and other industries, such as some important

parts of aircraft and spacecraft, and printing human teeth, bones, medical

implants, etc.

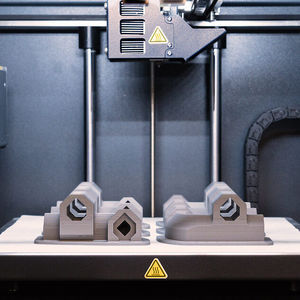

For laser 3D printing, which is relatively mature for printing high-precision

metal parts, spherical titanium powder of 15 to 53 microns is required. Now, the

project team mainly focuses on this aspect.

Spherical titanium powder for 3D printing in reality

The titanium rod is heated by the induction coil to melt the titanium rod,

and then the melted liquid titanium is "broken" by the high-pressure gas. In

this way, the titanium is broken into small droplets and solidified into a round

powder. Such a production method, called electrode induction gas atomization, is

currently one of the main methods for industrialized production of titanium

alloy powder in the world. One characteristic of titanium is that it cannot be

packed in crucibles because it will be contaminated. Difficulties in the

production process, one is the gas atomization and the stability of the

equipment, and the other is the fluidity of the powder. To this end, the team

spent a long time on the main research and development, and solved these

problems one by one.

As far as the current market is concerned, the price of spherical titanium

powder is about 230 to 300 US dollar per kilogram, which has a bright future.

However, although the research institute has achieved mass production and its

products have been recognized by customers, the current stage is still focusing

on scientific research, and it is necessary to further improve product quality

and gradually realize industrialization. With the continuous deepening of

research and development, this industry will eventually break the foreign

technology blockade. In the future, 3D printing will be applied to more fields

and benefit more people.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for Titanium Powder, please send an email to:

sales2@nanotrun.com

(Small Titanium Powder of Tens of Microns Can Print Key Parts of Aviation)