Discover a professional 3D printing powder supplier

(What is the Main Properties of Nitinol Alloys)

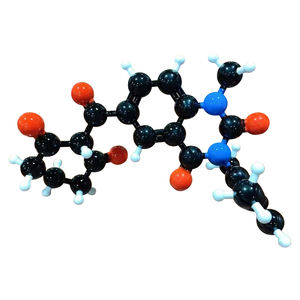

What is Nitinol?

Nitinol is a shape memory alloy, which is a special alloy that can

automatically restore its plastic deformation to its original shape at a certain

temperature. Its expansion rate is more than 20%, its fatigue life is up to 1×10

to the 7th power, its damping characteristic is 10 times higher than that of

ordinary springs, and its corrosion resistance is better than the best medical

stainless steel at present, so it can meet all kinds of engineering and It is an

excellent functional material for medical application requirements.

The main properties of Nitinol

In addition to the unique shape memory function, the memory alloy also has

excellent characteristics such as wear resistance, corrosion resistance, high

damping and super elasticity.

1. Shape memory characteristics: Shape memory is when the parent phase of a

certain shape is cooled from above Af temperature to below Mf temperature to

form martensite, the martensite is deformed at a temperature below Mf, and

heated to below Af temperature, accompanied by reverse phase Changes, the

material will automatically restore its shape in the parent phase. In fact, the

shape memory effect is a thermally induced phase transformation process of

Nitinol.

2. Superelasticity: The so-called superelasticity refers to the phenomenon

that the sample produces a strain much larger than the elastic limit strain

under the action of external force, and the strain can automatically recover

when unloaded. That is, in the state of the parent phase, due to the action of

the applied stress, the stress-induced martensitic transformation occurs, so

that the alloy exhibits a mechanical behavior different from that of ordinary

materials. Its elastic limit is much greater than that of ordinary materials,

and it is no longer obeyed. K’s law.

3. Corrosion resistance: Studies have shown that the corrosion resistance of

nickel-titanium wire is similar to that of stainless steel wire.

4. Sensitivity to temperature changes in the oral cavity: the orthodontic

power of stainless steel wire and CoCr alloy orthopedic wire is basically not

affected by the temperature in the oral cavity. The corrective force of the

super-elastic nickel-titanium alloy orthopedic wire changes with the change of

the oral cavity temperature. When the amount of deformation is constant. As the

temperature rises, the correction power increases. On the one hand, it can

accelerate the movement of teeth. This is because temperature changes in the

oral cavity will stimulate the blood flow in the stagnant blood flow due to the

capillary stagnation caused by the orthodontic device, so that the repair cells

can be fully nourished and maintained during the tooth movement. Its vitality

and normal function. On the other hand, orthodontists cannot precisely control

or measure the orthodontic force in the oral environment.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for nitinol powder, please send an email to:

sales2@nanotrun.com

(What is the Main Properties of Nitinol Alloys)