Compound chemical materials for 3D printing refer to a diverse class of advanced materials that combine two or more substances, often synthetic polymers, to create formulations with tailored properties for additive manufacturing processes. These materials go beyond traditional plastics and metals, encompassing composites, ceramics, and even bioinks, designed to expand the functionality and application scope of 3D printing. They are engineered to enhance properties such as strength, flexibility, thermal stability, conductivity, or biocompatibility, depending on the intended use.

Customizable Properties: By blending different chemicals and fillers, these materials can be designed to have specific mechanical, electrical, thermal, or optical characteristics.

Enhanced Performance: Compound materilas often outperform single single-component materials in terms of strength, heat resistance, or chemical resistance.

Functional Integration: They can incorporate functional elements like conductive fillers (e.g., carbon nanotubes) for electronics or biological components for tissue engineering.

Process Compatibility: Tailored to work with various 3D printing technologies, from Fused Deposition Modeling (FDM) to Stereolithography (SLA) and Inkjet Printing.

Sustainability: Some compounds incorporate recycled or bio-based materials, contributing to eco-friendly and sustainable manufacturing practices.

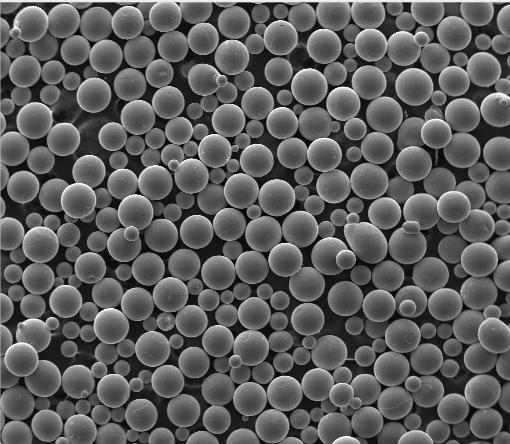

(BASSEN3D Molazon rigid resin for 3d printing)

BASSEN3D molazon rigid resin is a popular choice for 3D printing due to its high strength, flexibility, and durability. Here are some of the key parameters you may want to consider when choosing this resin: 1. Volume pergram (V) - The volume of molazon in grams per gram of resin is an important parameter to consider. It determines the amount of resin needed to produce a specific part or structure. 2. Crosslink density - The crosslink density of molazon refers to the number of strong interconnections between polymer chains. A higher crosslink density results in stronger and more durable parts. 3. Chemical stability - Molazon is resistant to moisture, chemicals, and other environmental factors that can damage traditional resins. Its chemical stability is important for long-term use and manufacturing of complex structures. 4. Print speed - The print speed of molazon can affect the time it takes to create a part or structure during 3D printing. It depends on several factors, such as the size and complexity of the part, the resolution of the printer, and the amount of resin used. 5. Print temperature - The print temperature of molazon affects the and melting rate of the resin. High temperatures can cause the resin to melt and flow easily, while low temperatures can result in slower printing speeds and reduced part quality. 6. Print bed temperature - The print bed temperature affects the speed and consistency of the print process. Higher temperatures can cause the print bed to dry out faster and reduce print accuracy, while lower temperatures can result in better print consistency. Overall, the choice of molazon rigidity resin for 3D printing depends on your specific needs and requirements. Consider these parameters along with any additional considerations, such as printing speed and cost, before making a decision.

(BASSEN3D Molazon rigid resin for 3d printing)

Advanced Manufacturing: Aerospace and automotive parts that require lightweight yet strong materials, such as carbon fiber reinforced thermoplastics for structural components.

Electronics: 3D printable conductive inks and resins for circuitry, sensors, and antennas, enabling rapid prototyping and customization in electronic device manufacturing.

Biomedical: Bioinks combining cells with supportive hydrogels for tissue engineering, organ modeling, and drug testing, pushing the boundaries of personalized medicine.

Consumer Products: Customized products with unique functionalities, such as flexible or color-changing materials for fashion, sports equipment, and home appliances.

Energy: Advanced battery and energy storage components, like solid-state electrolytes or porous structures for fuel cells, developed using compound chemical materials.

Company Profile

Kmpass is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

Q: Is BASSEN3D Molazon rigid resin for 3d printing more expensive than standard 3D printing materials? A: Generally, yes, due to its specialized formulations and enhanced properties. However, cost varies widely depending on the material composition and application.

Q: Can all 3D printers handle compound chemical materials? A: No, compatibility depends on the type of material and the printer technology. Some materials may require specific printer settings or hardware modifications.

Q: Is BASSEN3D Molazon rigid resin for 3d printing safe for users and the environment? A: Safety depends on the specific chemicals used. Many are developed with safety in mind, but it's crucial to follow handling guidelines and ventilation requirements.

Q: How do I choose the right compound material for my project? A: Consider the required end-use properties (mechanical, thermal, electrical), compatibility with your printer, and any regulatory or environmental constraints.

(BASSEN3D Molazon rigid resin for 3d printing)