Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

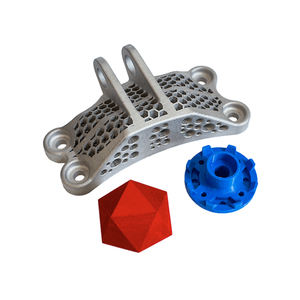

Overview of High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services)

Specification of High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services

Our solution offers top quality 3D printing solutions for commercial versions, rapid prototyping, and repair work needs. The modern technology supports custom-made designs customized to details job demands. Products include resilient options like ABS, PLA, nylon, and resin, making sure toughness and accuracy for commercial applications. Layer resolution reaches up to 0.05 mm, generating smooth surfaces and precise information.

The procedure begins with digital designs from clients. Data are checked for compatibility and maximized for printing. Engineers readjust specifications like wall density and infill density to fulfill efficiency criteria. Prototypes are built layer by layer making use of innovative FDM, SLA, or SLS printers. Production times vary by dimension and intricacy, with a lot of jobs completed within 24-48 hours.

Personalization is a top priority. Customers demand details measurements, structures, or mechanical buildings. Industrial sectors like automobile, aerospace, and producing use these designs for useful testing, tooling, or end-use components. Repair services take care of busted elements by scanning existing parts or using given plans. This decreases downtime and costs compared to standard replacement approaches.

Quality control makes sure every print satisfies rigorous criteria. Ended up items undertake visual evaluations, dimensional checks, and cardiovascular test if required. Changes are created any type of deviations. Support groups remain readily available throughout the procedure to resolve concerns or modifications.

Quick prototyping accelerates product development cycles. Designers repeat rapidly, screening numerous versions right away. The service suits tiny batches or single-unit manufacturing, avoiding mass-manufacturing expenditures. Repair solutions expand equipment life expectancy by restoring used or damaged parts to original specs.

Clients gain from cost financial savings, faster turnaround, and minimized waste. The modern technology adapts to varied industries, providing adaptability for unique challenges. Advanced printers deal with intricate geometries standard techniques can not achieve. This makes 3D printing suitable for custom-made tasks needing precision and resilience.

Technical assistance aids with documents preparation, material choice, and post-processing steps like sanding or painting. Shipping alternatives consist of reveal shipment for urgent orders. Data security procedures protect client styles throughout production.

(High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services)

Applications of High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services

Premium 3D printing services give customized remedies for industrial version development, quick prototyping, and part repair. These solutions assist businesses throughout sectors boost efficiency and decrease costs. Rapid prototyping is a crucial application. Business utilize 3D printing to turn digital styles into physical versions swiftly. This speeds up item advancement. Automotive, aerospace, and manufacturing markets count on this technology to examine concepts prior to automation. Errors obtain identified early, saving time and sources. Complicated geometries are attainable with accuracy, something traditional methods battle with.

Personalized commercial versions take advantage of 3D printing’s flexibility. Businesses produce exact replicas of machinery or components customized to specific needs. Architects and designers make use of detailed scale models for presentations or testing. Materials like long lasting plastics, steels, and resins make certain these versions hold up against real-world conditions. Adjustments are easy to make throughout the layout stage, reducing hold-ups.

Repair solutions using 3D printing resolve troubles with harmed or obsoleted parts. Producers typically encounter challenges finding replacements for ceased components. 3D printing replicates these parts accurately without waiting for vendors. Reverse design scans existing components to produce digital files for printing. Industries like heavy machinery and electronic devices use this to minimize downtime. Customized devices or fixtures are likewise generated on demand, reducing storage space costs.

The modern technology supports small-scale manufacturing runs. Businesses avoid the high costs of typical production configurations for limited sets. Medical tool manufacturers and robotics companies utilize this for specialized parts. 3D printing’s versatility makes it ideal for special tasks calling for quick changes.

Quality remains regular throughout all applications. Advanced printers and stringent top quality checks make sure integrity. This develops count on markets where accuracy issues. Firms incorporate 3D printing into workflows to stay affordable. The result is much faster innovation, reduced costs, and boosted analytic.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services

High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services: 5 FAQs

What materials are used for industrial 3D printing?

Industrial 3D printing uses durable materials suited for professional applications. Common options include plastics like ABS and nylon, metals like stainless steel and titanium, and specialty resins. Material choice depends on the project’s needs. Strength, heat resistance, and surface finish are key factors.

How accurate are the printed models?

Precision is critical for industrial prototypes. High-end printers achieve layer resolutions up to 0.05mm. This ensures tight tolerances and smooth surfaces. Complex geometries are replicated accurately. Post-processing steps like sanding or polishing further refine details.

What industries benefit most from these services?

Aerospace, automotive, manufacturing, and medical sectors use these services heavily. Functional prototypes, custom tooling, and end-use parts are common applications. Engineers and designers rely on rapid prototyping to test concepts quickly. Repair services fix broken machinery components efficiently.

How fast is the turnaround time?

Standard projects take 2-5 business days. Rush options are available for urgent needs. Speed depends on model size, material, and design complexity. Digital files are reviewed first to avoid delays. Shipping times vary by location.

Can existing parts be scanned and reproduced?

Yes. 3D scanning creates digital models of existing parts. This is useful for replicating discontinued components or repairing damaged machinery. The process ensures replacements match original specs. Modifications can be made to improve durability or functionality.

(High Quality 3D Printing Customized Industrial Model Rapid Prototyping and Repair 3D Printing Services)