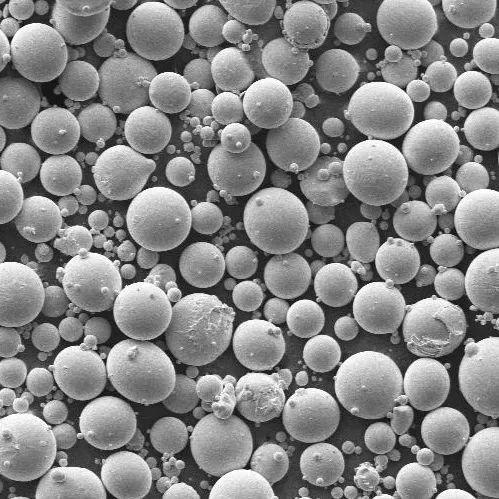

Overview of Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder

Titanium-based 3D printing, also known as Additive Manufacturing (AM) with titanium alloys, is an advanced manufacturing process that utilizes selective laser melting (SLM), electron beam melting (EBM), or binder jetting to fabricate complex geometries and functional parts directly from titanium powders. This technology leverages titanium's exceptional properties, including high strength-to-weight ratio, corrosion resistance, and biocompatibility, to create parts for demanding industries such as aerospace, medical, and automotive.

Features of Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder

Complex Geometry Fabrication: Enables production of intricate designs and internal structures impossible or extremely difficult with traditional manufacturing methods.

Material Efficiency: Reduces waste by using only the required amount of titanium powder, leading to material savings and environmental benefits.

Strength and Lightweight: Utilizes titanium’s natural properties to create lightweight yet strong components, essential for aerospace and performance-driven applications.

Customization: Facilitates the production of patient-specific medical implants and customized parts, taking advantage of 3D printing's design flexibility.

Reduced Lead Times: Streamlines manufacturing processes, allowing faster prototyping and production of parts compared to conventional methods.

(Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder)

Ti64 G5 titanium alloy powder is an effective addition to 3D printing to create a strong and durable material for manufacturing aerospace, medical, automotive, industrial, and other applications. The following parameter specifies the properties of Ti64 G5 titanium alloy powder used in additive manufacturing: 1.: Ti64 G5 is the name of the raw material used to produce this powder. 2. Application: Ti64 G5 titanium alloy powder is commonly used in additive manufacturing to create aerospace, medical, automotive, industrial, and other applications that require high strength, durability, and resilience. 3. Particle size: The particle size refers to the size of individual atoms within the powders. In general, Ti64 G5 titanium alloy powder has a size range from 0.2-0.7 nanometers. 4. Разulation: Ti64 G5 titanium alloy powder can be divided into different fractions based on its application requirements, such as focused powder or drop powder. A focused powder is often used for processing precise parts with fine grain sizes, while drop powder is used for creating larger, more uniform components. 5. Može be ground to specific grain sizes: Depending on the application, Ti64 G5 titanium alloy powder may need to be ground to specific grain sizes. This process involves mixing the powder with a suitable medium and then rotating it at a high speed until the desired material properties are achieved. 6. Formation temperature: The formation temperature of Ti64 G5 titanium alloy powder is also important for achieving the desired materials properties. Common types of powder include powders with high Mohr-content and low melting points, which results in powders with high tensile and stretchability. 7. Collaboration with accelerators: To improve the performance of the powder in various applications, it may be necessary to collaborate with accelerators. Accelerators offer powerful machinery and tools for operating the powder in real-time, allowing for faster completion rates and improved productivity. Overall, Ti64 G5 titanium alloy powder provides a versatile option for adding advanced materials to 3D printing applications. Its high particle size, optimization for specific application requirements, and strong ground-to-specific grain sizes make it ideal for providing durable and functional components for a wide range of industries.

(Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder)

Applications of Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder

Aerospace: Manufacturing of lightweight turbine blades, structural components, and engine parts that can withstand high temperatures and stress.

Medical Implants: Producing customized implants like hip joints, cranial plates, and dental implants, which benefit from titanium's biocompatibility and tailor-made designs.

Automotive and Racing: Creating high-performance parts such as exhaust systems, suspension components, and engine parts for reduced weight and enhanced performance.

Defense: Fabricating lightweight armor and tactical gear, taking advantage of titanium's strength and durability.

Energy: Manufacturing components for the oil & gas industry and renewable energy sectors, where corrosion resistance and durability are crucial.

Company Profile

Kmpass is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder

Q: Is Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder cost-effective? A: While the initial setup and material costs can be high, the technology reduces waste and allows for complex designs, which can lead to cost savings in specific applications and volumes.

Q: What are the common titanium alloys used in 3D printing? A: Popular titanium alloys include Ti-6Al-4V (titanium with 6% aluminum and 4% vanadium), known for its balanced properties, and Ti-6Al-4V ELI, used for biomedical applications due to its enhanced ductility.

Q: Can Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder match the strength of traditionally manufactured titanium parts? A: Yes, with proper post-processing, including heat treatment, titanium 3D printed parts can achieve mechanical properties comparable to, and in some cases, exceed those of forged or cast titanium parts.

Q: Are there any limitations to titanium 3D printing? A: Some limitations include high equipment costs, post-processing requirements, and the need for specialized design considerations to prevent part distortion and ensure structural integrity.

Q: How does Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder impact the environment? A: While the process consumes significant energy, it promotes sustainability by reducing material waste and enabling lightweight designs that improve fuel efficiency in transportation industries.

(Ti64 G5 Titanium Alloy Powder For Additive Manufacturing (3D printing) powder)